Home / Caterpillar Service Manuals / Cat C11/C13/C15 (serial KCA, KCB, JAM & BXS) / Caterpillar C11 & C13 Systems Operations, Testing & Adjusting Manual (sn KCA & KCB) Caterpillar C11 & C13 Systems Operations, Testing & Adjusting Manual (sn KCA & KCB) $ 109.95. Caterpillar C11 and C13 Specifications Manual On-Highway Engines 141 pages. CAT C11, C13, C15, C18 Industrial Engines troubleshooting manual 196 pages.

- Loosen valve adjustment locknut (1). CAT C15, Manual de Operacion y Mantenimiento, 106 pagina, Haga clic para descargar Diesel Engine Specs Basic specs are free and open to everyone They usually include engine images, displacement, dimensions and weight, essential bolt tightening torques, plus characteristics of the engine e.g.

- Document about Cat C13 Valve Adjustment Manual Download is available on print and digital edition. This pdf ebook is one of digital edition of Cat C13 Valve Adjustment Manual Download that can be search along internet in google, bing, yahoo and other mayor seach engine.

- C13 valve train like it's earlier cousin the 3176 has valve train issues. Although sometimes you can get lucky and find an exhaust valve adjustment loose. If the adjustment is loose it won't allow the cylinder to purge the exhaust gases completely on the exhaust stroke and some remains trapped in the cylinder until the intake valve opens and it.

Note: Valve lash is measured between the rocker arm and the valve bridge. All measurements and adjustments must be made with the engine stopped and the valves fully closed.

Valve Lash Check

An adjustment is not necessary if the measurement of the valve lash is in the acceptable range in Table 1.

| Inlet Valves | Exhaust Valves | |

|---|---|---|

| Valve Lash (Stopped Engine) | 0.38 ± 0.08 mm (0.015 ± 0.003 inch) | 0.81 ± 0.080 mm (0.032 ± 0.003 inch) |

| TC Compression Stroke | 1-2-4 | 1-3-5 |

| TC Exhaust Stroke (1) | 3-5-6 | 2-4-6 |

| Firing Order | 1-5-3-6-2-4 (2) | |

Cat C13 Valve Adjustment Manual Diagram

( 1 ) 360° from TC compression stroke

( 2 ) The No. 1 cylinder is at the front of the engine.

If the measurement is not within this range, an adjustment is necessary. Refer to “Valve Lash Adjustment” for the proper procedure.

Valve Lash Adjustment

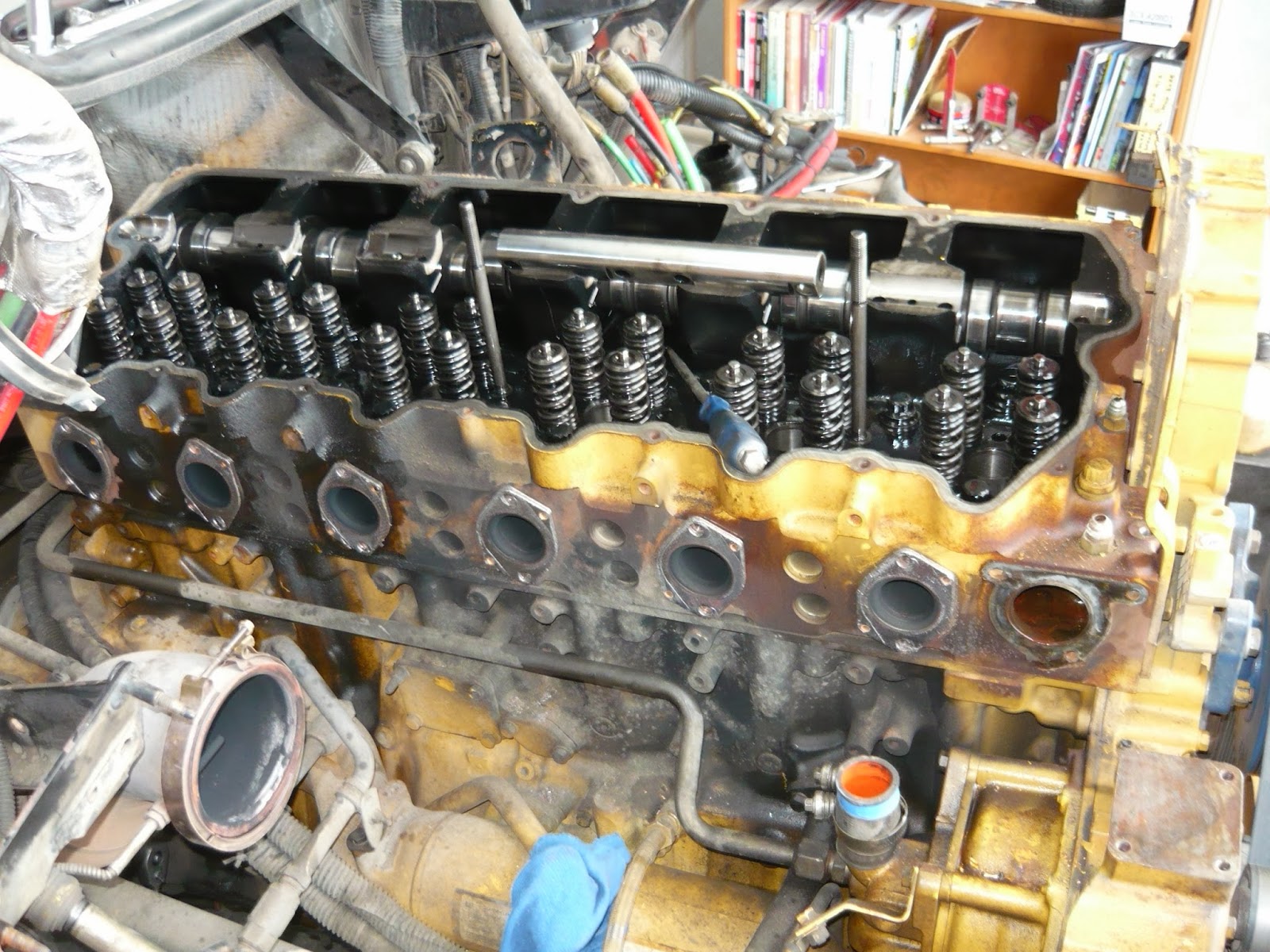

Illustration 1 g01373511

Cylinder and valve location

(A) Exhaust valves

(B) Inlet valves

Use the following procedure to adjust the valve lash:

- Put the No. 1 piston at the top center position on the compression stroke. Refer to Testing and Adjusting, “Finding Top Center Position for No. 1 Piston”.

Table 2 TC Compression Stroke Inlet Valves Exhaust Valves Valve Lash 0.38 ± 0.08 mm

(0.015 ± 0.003 inch)0.81 ± 0.080 mm

(0.032 ± 0.003 inch)Cylinders 1-2-4 1-3-5

- Adjust the valve lash according to Table 2.

- Lightly tap the rocker arm with a soft mallet. This action will ensure that the lifter roller seats against the base circle of the camshaft.

- Loosen the adjustment locknut.

- Place the appropriate feeler gauge between rocker arm and the valve bridge. Then, turn the adjustment screw in a clockwise direction. Slide the feeler gauge between the rocker arm and the valve bridge. Continue turning the adjustment screw until a slight drag is felt on the feeler gauge. Remove the feeler gauge.

- Tighten the adjustment locknut to a torque of 30 ± 7 N·m (22 ± 5 lb ft). Do not allow the adjustment screw to turn while you are tightening the adjustment locknut. Recheck the valve lash after tightening the adjustment locknut.

- Remove the timing bolt and turn the flywheel by 360 degrees in the direction of engine rotation. This action will put the No. 6 piston at the top center position on the compression stroke. Install the timing bolt in the flywheel.

Table 3 TC Exhaust Stroke Inlet Valves Exhaust Valves Valve Lash 0.38 ± 0.08 mm

(0.015 ± 0.003 inch)0.81 ± 0.080 mm

(0.032 ± 0.003 inch)Cylinders 3-5-6 2-4-6

C13 Valve Adjustment

- Adjust the valve lash according to Table 3.

- Lightly tap the rocker arm with a soft mallet. This action will ensure that the lifter roller seats against the base circle of the camshaft.

- Loosen the adjustment locknut.

- Place the appropriate feeler gauge between rocker arm and the valve bridge. Then, turn the adjustment screw in a clockwise direction. Slide the feeler gauge between the rocker arm and the valve bridge. Continue turning the adjustment screw until a slight drag is felt on the feeler gauge. Remove the feeler gauge.

- Tighten the adjustment locknut to a torque of 30 ± 7 N·m (22 ± 5 lb ft). Do not allow the adjustment screw to turn while you are tightening the adjustment locknut. Recheck the valve lash after tightening the adjustment locknut.

- Remove the timing bolt from the flywheel after all adjustments to the valve lash have been made. Reinstall the timing cover.

Cat C13 Valve Adjustment Manual Download

Refer to Testing and Adjusting, “Electronic Unit Injector – Adjust”.